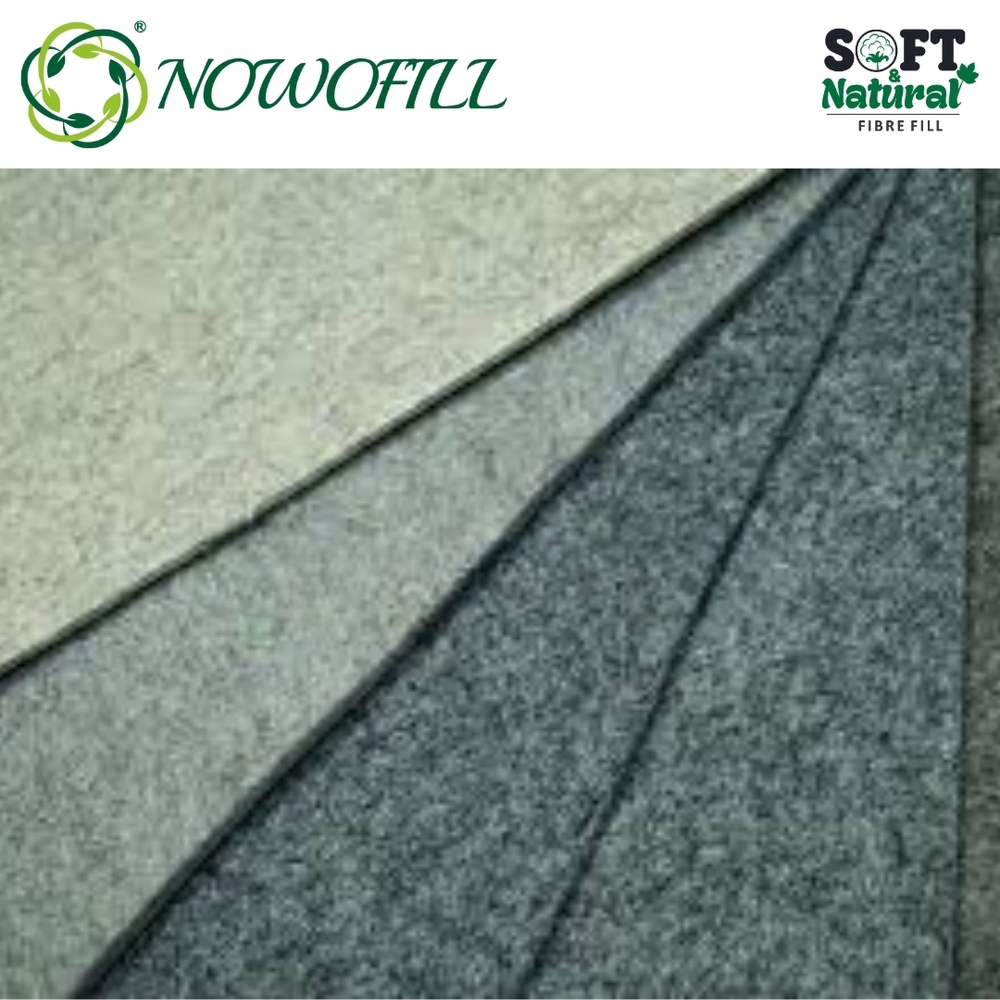

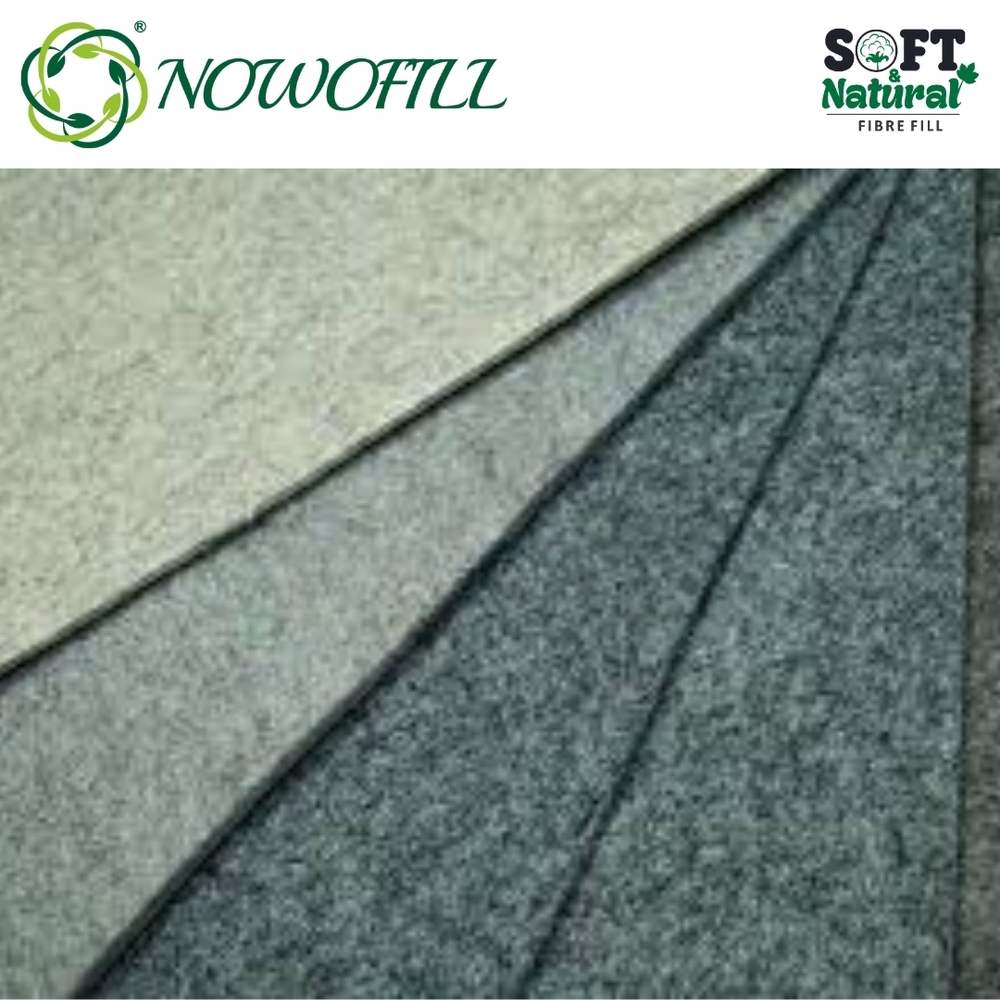

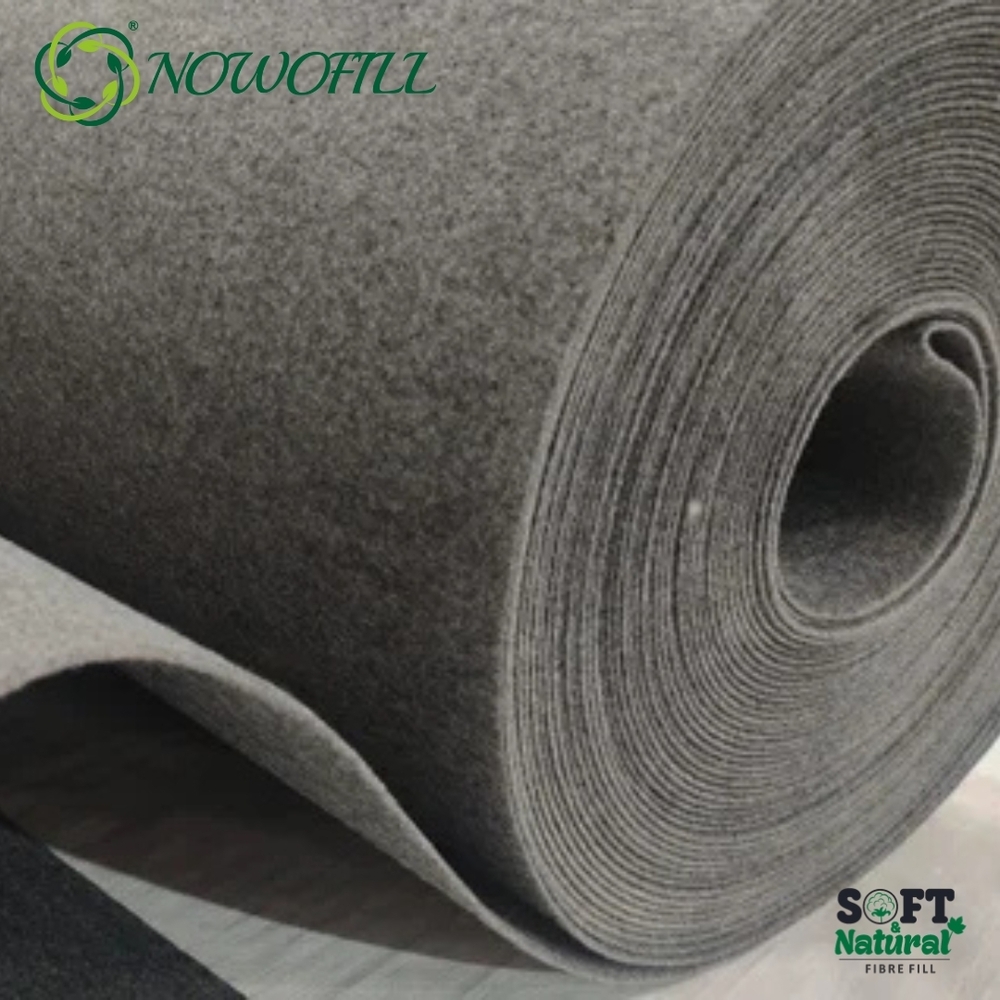

Needle Punch Polyester Felts. .

Price 60 INR/ Meter

Needle Punch Polyester Felts. . Specification

- Application

- Carpet backing and flooring underlay

- Pattern

- Plain

- Usage & Applications

- Filling material

- Material

- Polyester

- Print Type

- Plain

- Color

- Grey

- GSM

- 200

- Width

- 150-600 Meter (m)

- Fabric Type

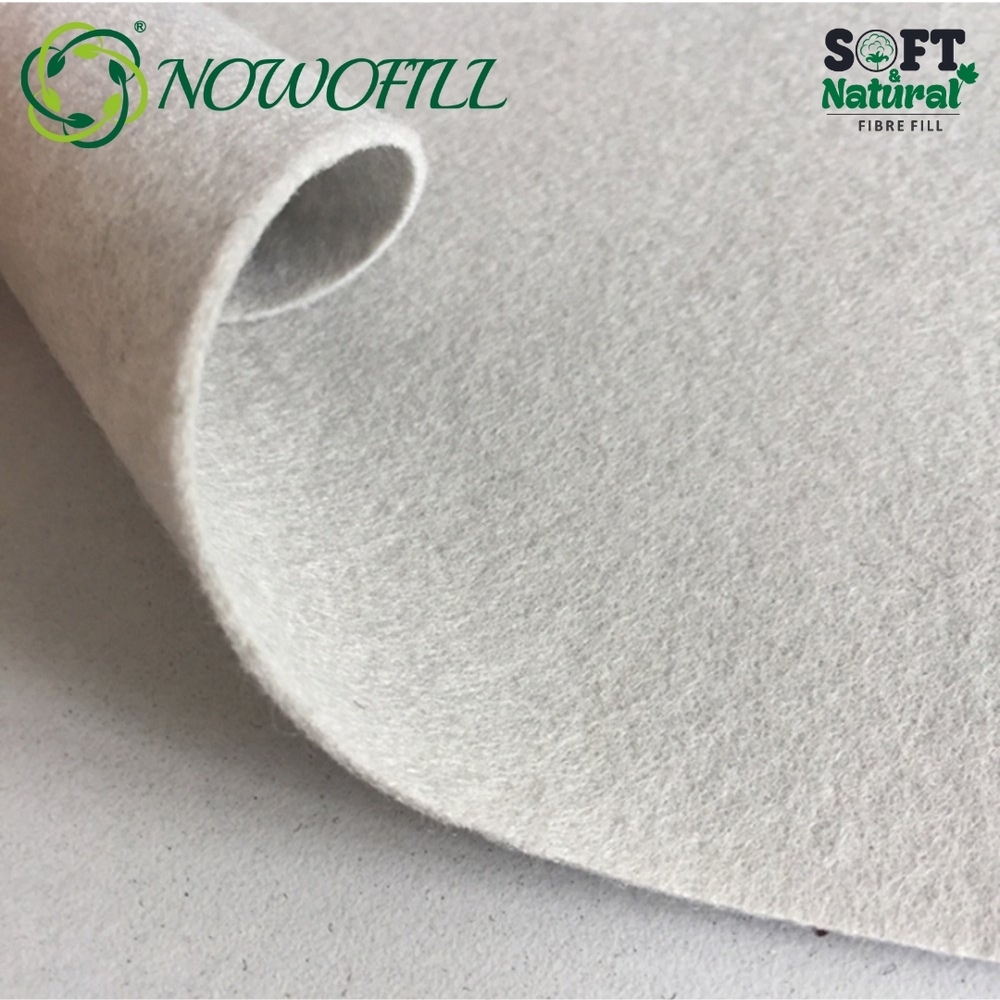

- Needle Punch

- Texture

- Other

- Style

- Plain

- Technique

- Needle Punching

- Abrasion Resistance

- High

- Chemical Resistance

- Resistant to Mild Acids and Alkalis

- Packing

- Rolls or Sheets, Wrapped with PE Film

- Edge Treatment

- Heat Cut or Laser Cut

- Water Absorption

- Less than 1%

- MOQ

- 500 kg

- Elongation

- Low

- Custom Thickness and Sizes

- Available Upon Request

- Shrinkage

- Minimal

- Air Permeability

- High

- Porosity

- Customizable

- Hardness

- Soft to Medium

Needle Punch Polyester Felts. . Trade Information

- Minimum Order Quantity

- 1000 Meter

- FOB Port

- LDPE jute

- Payment Terms

- Paypal, Cash in Advance (CID)

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Needle Punch Polyester Felts. .

Nowofill Needle punch polyester felts are nonwoven fabrics made by mechanically interlocking polyester fibers using a needle-punching process. These felts are durable, flexible, and resistant to chemicals, moisture, and environmental stress. They offer excellent filtration, insulation, cushioning, and sound absorption properties. Needle punch polyester felts are widely used in industrial, commercial, and domestic applications where strength and reliability are essential. Common uses include automotive interiors, soundproofing and acoustic panels, furniture padding, mattress and bedding layers, HVAC filters, carpet backing, and protective packaging. Their versatility, dimensional stability, and long service life make them ideal for a wide range of engineering and home textile applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Punch Felt Category

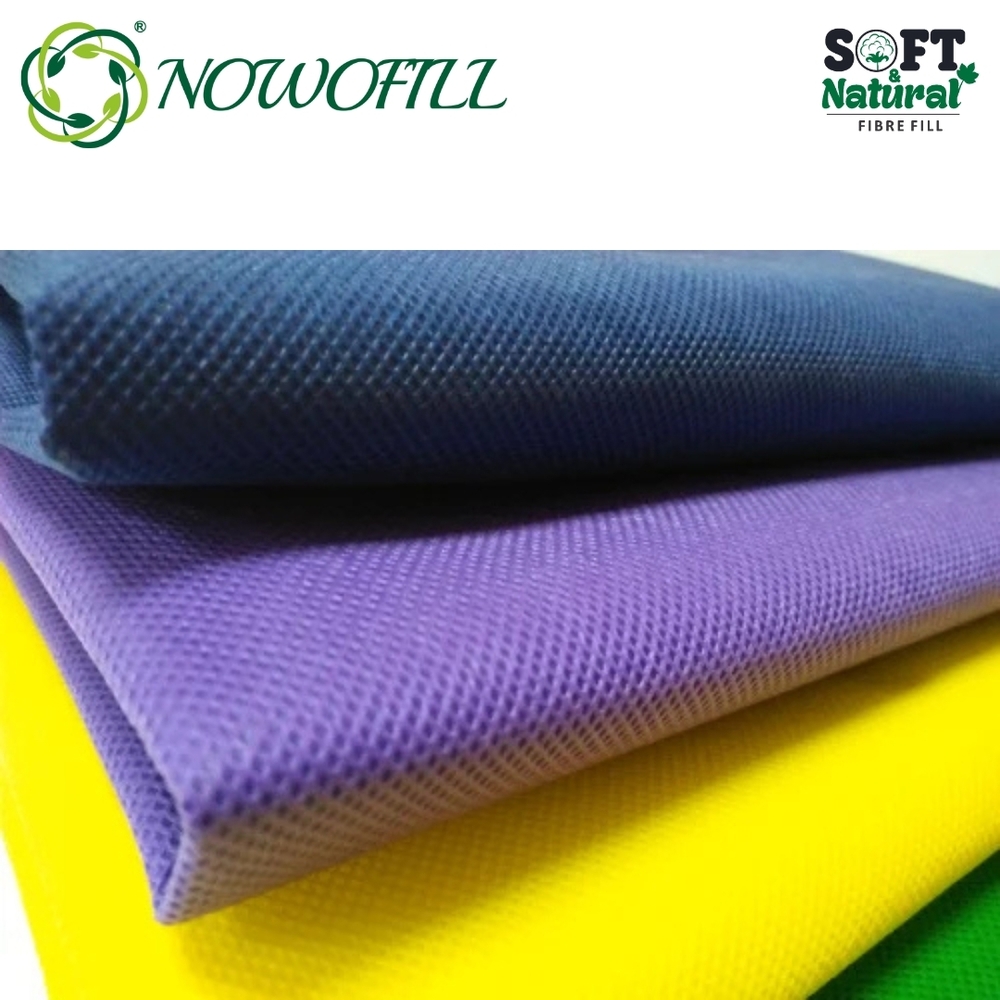

Polyester Needle Punch fabric .

Price 60 INR / Meter

Minimum Order Quantity : 1000

Fabric Type : Needle Punch

Width : 16 Meter (m)

Texture : Dyed

GSM : 200

BS5852 Fire Retardent Viscose needle punch For Furniture and Sofa .

Price 105 INR / Meter

Minimum Order Quantity : 1000

Fabric Type : Needle Punch

Width : 4045 Inch (in)

Texture : Non Woven

GSM : 200

Needle Punch Fabric for Water Absorption.

Price 75 INR / Meter

Minimum Order Quantity : 1000

Fabric Type : Polyester Wadding

Width : 150600 Meter (m)

Texture : Other

GSM : 200

Non Woven Needle punch Felt .

Price 35 INR / Meter

Minimum Order Quantity : 5000

Fabric Type : Nonwoven

Width : 5000 Meter (m)

Texture : Non Woven

GSM : 150

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS