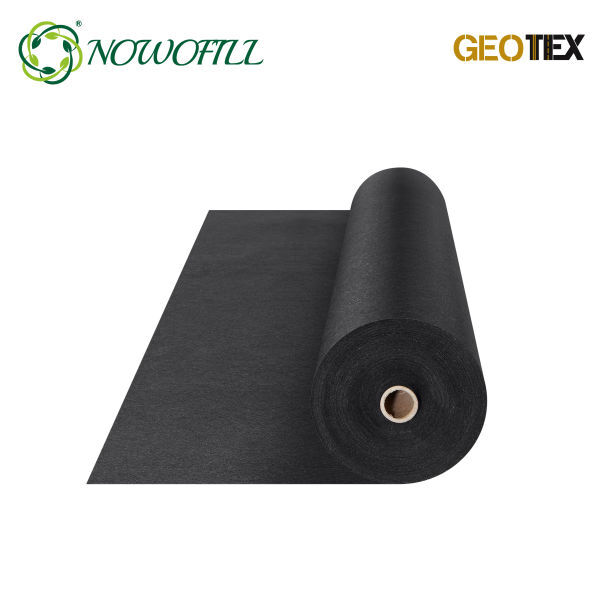

Geofabrics .

Price 18 INR/ Square Meter

Geofabrics . Specification

- Fabric Type

- Geotextile

- Application

- Soil erosion control and slope protection

- GSM

- 150

- Print Type

- Plain

- Usage & Applications

- Filling material

- Color

- Black

- Material

- Polyester

- Width

- 1-6 Meter (m)

- Characteristics

- Tear-Resistant, Environmental Friendly, Light in Weight

- Disposable

- Yes

Geofabrics . Trade Information

- Minimum Order Quantity

- 1000 Square Meters

- FOB Port

- LDPE Jute

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Geofabrics .

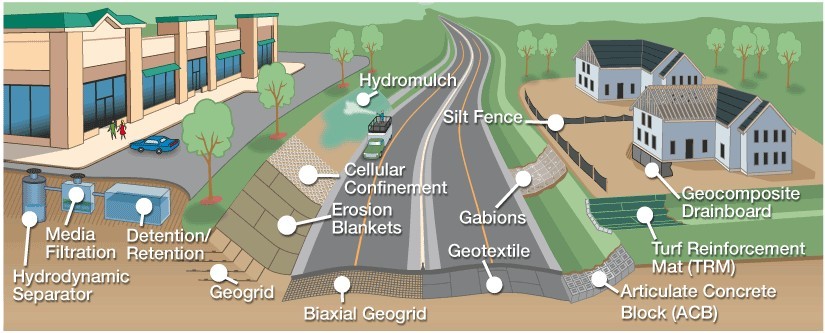

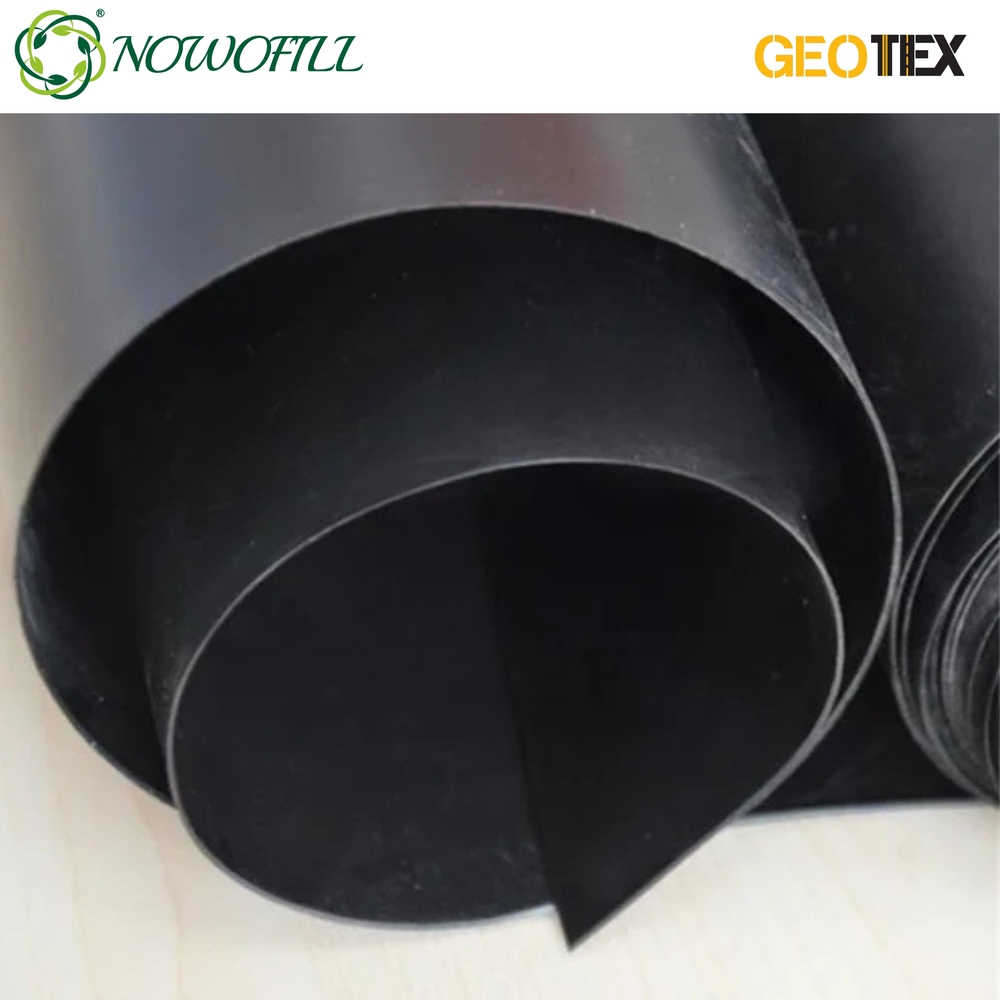

Nowofill Geofabrics are permeable textile materials used in civil engineering and construction to improve soil performance and ground stability. Made from synthetic fibers such as polyester or polypropylene, geofabrics are available in woven and nonwoven forms. They perform key functions like separation, filtration, drainage, reinforcement, and erosion control by allowing water to pass through while retaining soil particles. Geofabrics are durable, resistant to chemicals and weathering, and suitable for long-term use. They are widely used in road and railway construction, riverbank protection, landfills, drainage systems, slope stabilization, waterproofing, and various infrastructure and environmental projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Geotextlie Non Wovens Fabric Category

Pipe rapping Geotextile. .

Price 26 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Color : Black

Usage & Applications : Filling material

Width : 16 Meter (m)

Material : Polyester

Nonwoven Geotextile for slope protection.

Price 26 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Color : White,Black

Usage & Applications : Filling material

Width : 16 Meter (m)

Material : Polyester

PP/ Polyester Non Woven Geotextile For Railroad Ballast Separation.

Minimum Order Quantity : 1500 Square Meters

Color : White

Usage & Applications : Filling material

Width : 16 Meter (m)

Material : Polyester

Geotextile For landfill.

Price 32 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Color : White

Usage & Applications : Filling material

Width : 16 Meter (m)

Material : Polyester

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free